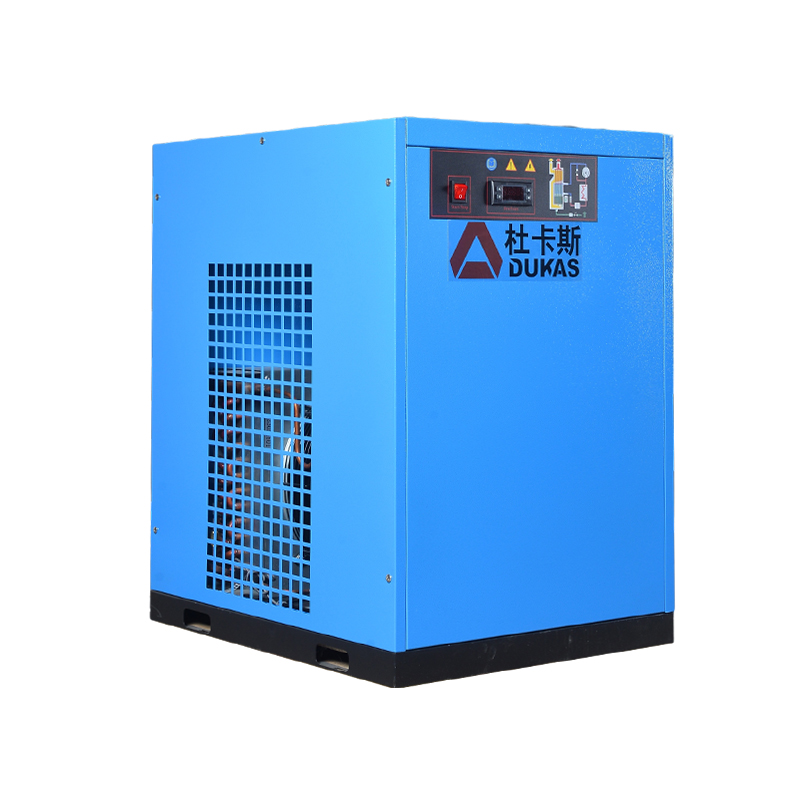

Refrigeration dryer is a device that uses refrigeration technology to dry compressed air. Its working principle is to use the refrigeration effect of the refrigerant to condense the moisture in the compressed air into water droplets, and then remove the moisture through the filter device to obtain dry compressed air. This process mainly involves core components such as compressors, condensers, evaporators and steam-water separators.

Most common cold dryers on the market are calibrated to have a pressure dew point of 2-10°C, for example, the dew point temperature is 10°C at a pressure of 0.7Mpa; when the pressure drops to atmospheric pressure, the corresponding dew point temperature is -16°C. Therefore, there is no problem in using a cold dryer in winter. However, it is still necessary to pay attention to its operating status and efficiency in use and management to prevent failures that may cause gas supply interruptions and equipment shutdowns.

1. Precautions for use in winter

Prevent freezing

Protection of water pipes, valves and compressors: When the temperature is low in winter, the moisture in the equipment is easy to freeze, which may cause damage to water pipes, valves and compressors. Therefore, the equipment needs to be preheated before use to ensure that the operating temperature is not lower than 0°C. In addition, these parts should be checked regularly for ice formation and should be dealt with immediately if found.

Indoor temperature control: When using the refrigerated dryer in winter, the indoor temperature should be reasonably controlled to avoid adverse effects on the equipment due to too low ambient temperature.

Refrigerant selection

Performance is affected by temperature: The performance of refrigerants changes with changes in temperature. In winter, due to lower temperatures, the cooling effect of the refrigerant may decrease, thus affecting the drying effect of the equipment. Therefore, it is necessary to reasonably select the refrigerant according to ambient temperature, humidity and other conditions to ensure the normal operation of the equipment.

Warm-up operation

Necessity: Preheating ensures a moderate temperature inside the equipment and prevents water pipes, valves and compressors from freezing due to low temperatures. Preheating can also circulate the refrigerant more fully and improve drying efficiency.

Operation method: Before use, you can start the preheating device or run the equipment for a period of time to preheat. The preheating time depends on the equipment model and outdoor temperature. It is generally recommended to preheat 30 minutes before starting the equipment.

Regular inspection and maintenance

Inspection content: The status of the water pipes, valves, compressors and refrigerants of the equipment should be checked regularly to ensure that they are in good working condition. In addition, check the drainage of the soda and water separator to ensure that the drainage is smooth and unobstructed.

Maintenance method: Any problems or abnormalities found should be handled and maintained in a timely manner. For example, if the water pipe is found to be frozen, it should be stopped immediately to defrost it; if the refrigerant is found to be insufficient or the performance is degraded, the refrigerant should be replenished or replaced in time.

2. Advantages and challenges of winter use

Advantages

High cooling efficiency: In winter, due to the lower ambient temperature, the cooling efficiency of refrigerated dryers is usually higher. This helps achieve a lower dew point temperature, thereby improving drying results. Reduced energy consumption: Compared with the high temperature and high humidity environment in summer, the low temperature and low humidity environment in winter is conducive to reducing the energy consumption of the equipment. Because the equipment does not need to consume too much energy to combat the effects of high temperature and high humidity on the drying effect.

3. Increased risk of freezing: As mentioned before, the moisture inside the equipment is easy to freeze in low-temperature environments in winter, which poses a threat to the normal operation of the equipment. Decreased refrigerant performance: Although cooling efficiency is high in winter, refrigerant performance may also be affected by low temperatures and decrease. This requires greater caution in the selection and use of refrigerants.

4. Optimization strategies and suggestions

Strengthen insulation measures

Pipe insulation: Insulate water pipes, valves and other parts of the equipment to reduce heat loss and the risk of freezing. Computer room insulation: If the equipment is installed in the computer room, the computer room can be insulated to improve the temperature stability in the computer room.

Use anticoagulants

Adding the right amount of anticoagulant inside the equipment can lower the freezing point of water, thereby reducing the risk of freezing. However, it should be noted that the use of anticoagulants should comply with equipment requirements and relevant standards.

Adjust operating parameters

Adjust the operating parameters of the equipment, such as refrigerant flow, compressor speed, etc., according to ambient temperature and humidity to optimize the equipment’s operating effect and energy consumption.

Strengthen monitoring and early warning

Monitor the operating status and parameter changes of the equipment in real time, and handle any abnormalities immediately if any abnormalities are found. At the same time, an early warning mechanism is established to detect potential problems in advance and take corresponding measures to prevent them.

Training and guidance

Provide professional training and guidance to operators to improve their operating skills and safety awareness. This helps reduce equipment failures and safety incidents caused by improper operation.

To sum up, the refrigerated dryer can be used in winter, but care needs to be taken to prevent water pipes, valves and compressors from freezing. Through reasonable selection of refrigerants, strengthening insulation measures, using anticoagulants, adjusting operating parameters, and strengthening monitoring and early warning, the normal operation of the equipment and extended service life can be ensured. At the same time, professional training and guidance for operators is also an important means to improve equipment operating efficiency and safety.

Post time: Oct-21-2024